Overview

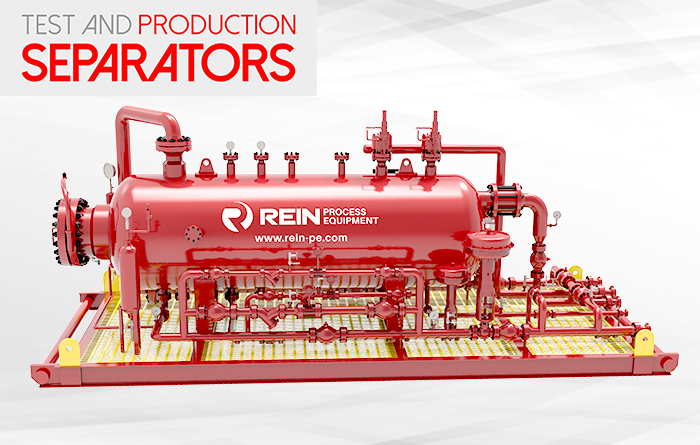

Horizontal Test Separator is a mechanical assembly with high-precision instruments designed to separate well fluids into oil, water, gas.

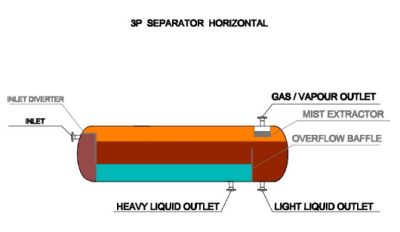

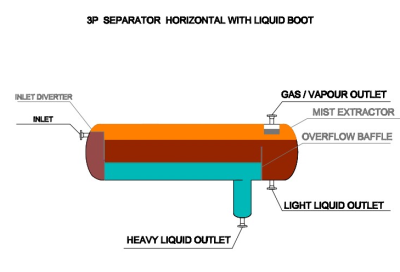

Below is simple illustration of separation into three phases in typical horizontal vessel and horizontal vessel with liquid boot.

Horizontal Test Separator is a mechanical assembly with high-precision instruments designed to separate well fluids into oil, water, gas.

Below is simple illustration of separation into three phases in typical horizontal vessel and horizontal vessel with liquid boot.

Horizontal Test Separator consists of following sections

Mechanical

· Pressure Vessel with Internals

· Piping

· Base and Frame (Skid)

Level Control

· Level transmitter

· Mechanical Pneumatic Level Controller

· Control Valves

· Sight Glasses (Level gauge)

Pressure Control

· Pressure Control Valve and Pressure Controller

· Pressure and Temperature Transmitters

· Safety Valves

· Rupture discs

Flow metering and recording

· Orifice Plate & Fitting

· Coriolis Flowmeter

· Turbine Flowmeter

· Flow analyzers

· 3-Pen Chart Recorder

· Flowmeter tube and flow conditioner

Valves

· Ball Valve

· Check Valve

· Safety Valves

· Control Valves

· Y-type Strainer

· Needle Valve

Any horizontal test separator shall be designed based on the characteristics of flow stream and environmental conditions.

Working media of horizontal test separators can be:

· gas

· condensable liquid vapors

· water

· water vapor

· crude oil

· solid debris

Hydrocarbon wells can be classified as:

· Crude oil well

· Dry gas well

· Gas condensate well

Horizontal Test Separator can be designed as several standards based on the area of application or applied standards by the clients.

The most applied standards nowadays are ASME and API standards, which are American standards. Separator is designed as per API 12J, while pressure vessel is designed as per ASME VIII, Div1/2.

In Russia, separator is designed as per GOST standard and manufacturer’s own specification, while in China, GB150 is applied for pressure vessel design of separator.

Construction material of test separators is usually carbon steel (SA 516 Gr 70N), while removable internals are fabricated using stainless-steel materials (SS316). Skid is also designed from construction carbon steels like Q36 or Q235.

Sour service separator shall comply with required or local requirements for high-corrosion materials, such as NACE MR0175, ISO 15156, or SY/T0599. Some clients may require HIC and SSC test, but usually most of the client does not require these tests as fees for these tests are high, and period of testing significantly influences delivery period. Generally, operation in acid/sour gas fields can be done without HIC or SSC tests, as certain material already ensures reliable application in H2S- and CO2-rich flow streams. Corrosion allowance shall be taken into consideration when pressure vessel is designed.

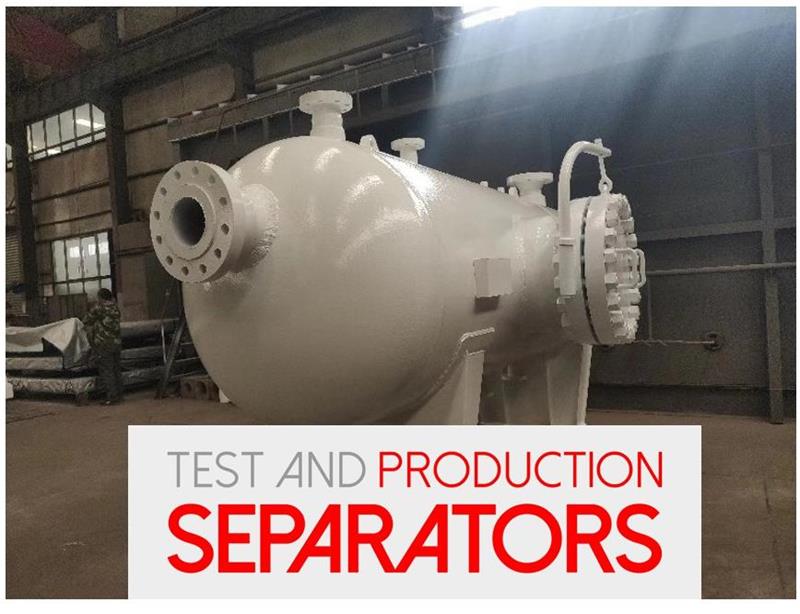

Picture of pressure vessel for horizontal three phase separator. Manufactured in China.

Pressure vessel is very important component of separator skid. Pressure vessel shall be designed as per code & standards with all necessary calculation for strength and operation conditions. Raw materials shall be supplied from reliable and certified mills, while factory quality inspector shall conduct factory acceptance test and inspections. Process of pressure vessel fabrication consist of several stages, such as, cutting, bending, welding, nozzle welding, internal welding, test & inspection, heat treatment, NDT, removable internal assembly, coating & painting.

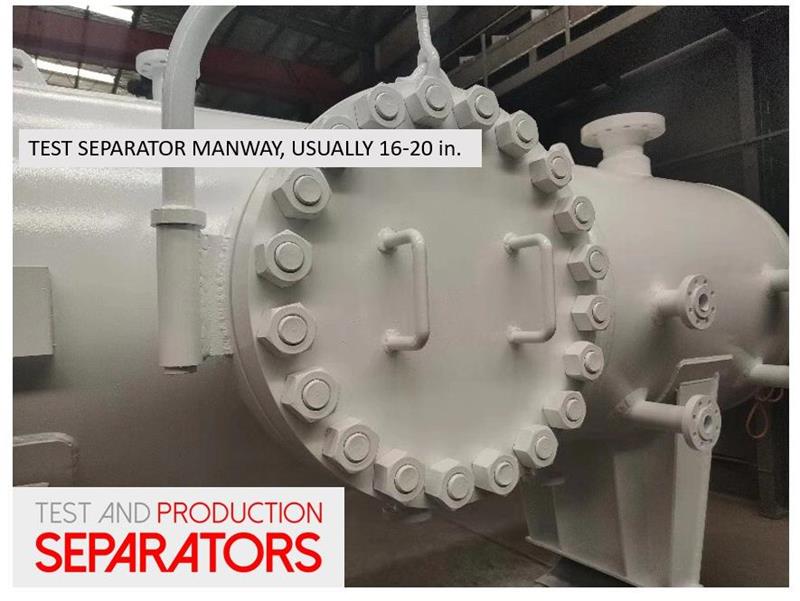

Separator Manway

Manway is a mechanical section of pressure vessel, which provides access to the separator’s internals when maintenance or inspection of separator internals is required.

Horizontal Separator sizing depends on flow rate and application space limits. Widely applied diameters are 30 in., 36 in., 42 in., 48. While length can be designed as 8ft., 10 ft., 12 ft., 15 ft.

Pressure ratings are: 250 psi, 750 psi, 1440 psi, 2160 psi.

Feel free to contact us to receive more information and purchase guidance for separators from China! We will be glad to provide you assistance and free consultations.