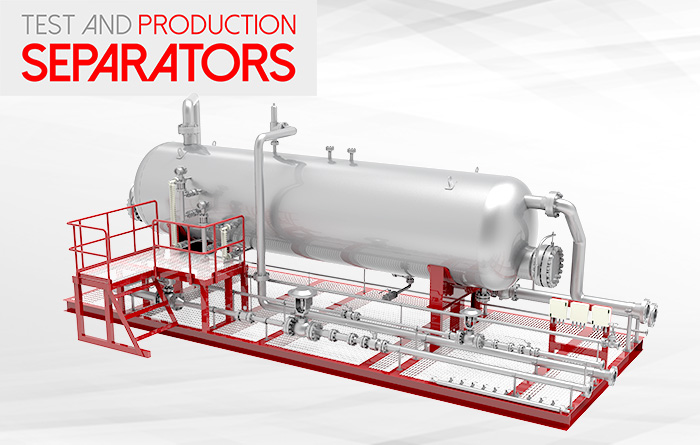

Overview

Production Separator is a special equipment used oilfield for oil and gas production. Typical Production Separator consist of following components:

Production Separator is a special equipment used oilfield for oil and gas production. Typical Production Separator consist of following components:

· Separator Vessel with internals

· Level Control Instruments and Valves

· Control and Open/Close Valves

· Instruments, such as gauges and transmitter for displaying and signal transmission of pressure, temperature and level

· Safety devices, such as safety valve, rupture discs, ESD system

· Insulation and heat tracing (for cold regions)

· Air supply instruments and other instrument air pipe and fittings

· Signal and power cables

· Cable trays

· Flow analyzers

· Flow meters

· Frame and other steel structures, such as ladder, service platform

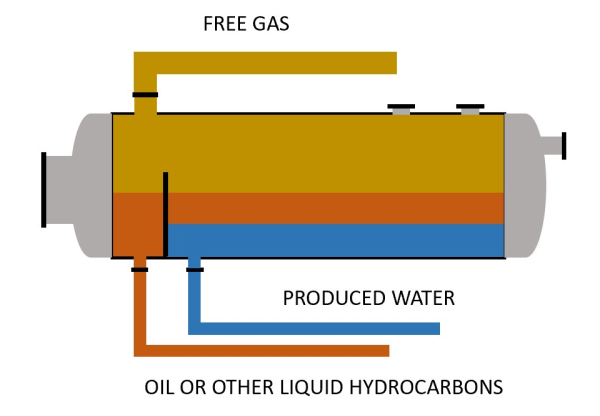

The primary function of three phase production separator is to separate coming steam into three phases, oil, was and gas. Depending on the process design, several production separators, such as High-Pressure (HP) separator or Low-pressure (LP) separators, can be used in oil and gas production.

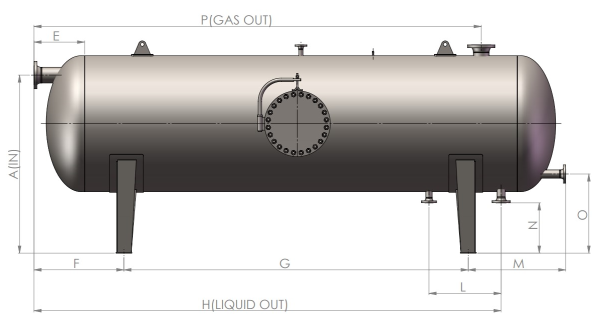

Separator Vessel

Separator vessel is a main chamber for holding liquids and gas for certain period of time (known as retention time). Separator vessel is designed based on flow rate, working pressure, working temperature, composition of the liquid and operational requirements of the client. One of the widely practiced standards is ASME, while pressure vessel standards may vary from country to country. In China, GB150 is applied, while in Russia, it is GOST standard that regulates design and fabrication of the pressure vessels for production separator.

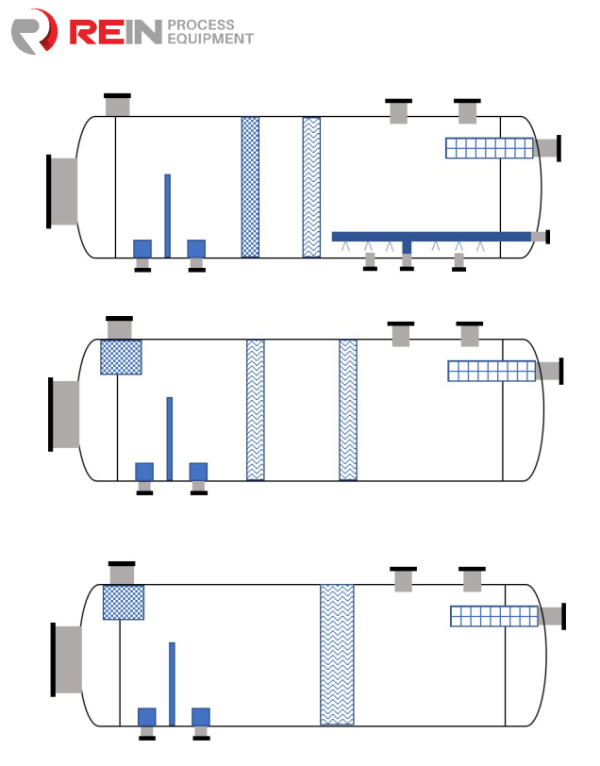

Separator internals

Separator internals are sets of packings used for increasing separation efficiency and conditioning flow inside of separator. Typical separator internals are inlet diverters, coalescer packs, flow conditioners, wave breakers, vortex breakers, vane packs, mist extractors. Replaceable separator packings are usually made from stainless steel, while other internals that welded to the separator vessel are made from carbon steel.

Picture below shows structure of typical three phase horizontal production separator

Picture below shows separation of media into three phases.

Picture below shows typical arrangement of separator internals of two scenarios.

Current data is provided by Separator engineering and fabrication companies in China. Contact us for more information.