What is Gas Cyclone Separator?

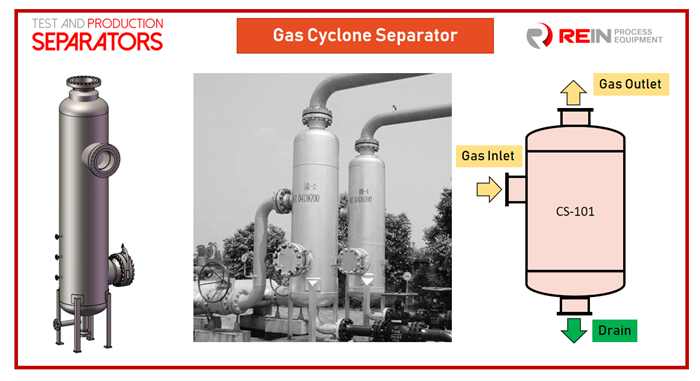

Cyclone separator is another type of gas-liquid two-phase separators, which performs droplet separation by radial or centrifugal force. Cyclone separator consists of inclined tangential inlet, tangential liquid outlet, and axial gas outlet. Gas-liquid cylindrical cyclones used as the part of well test or metering package.

Gas and liquids are separated by centrifugal force as the first-stage separation, demister catches the liquid drops from the gas going to the outlet performing the secondary gas-liquid separation. The special cylindrical form of the separator and the incoming liquid flow create tangential rotating flow. The liquid with higher density has larger centrifugal pull and moved to the vessel wall while the liquid with lower density has smaller centrifugal pull and is forced to the center of the vessel. If the incoming medium is a mixture of immiscible liquids, such as oil and water, they will be coarsely separated into a water rich flow and an oil rich flow, which make following liquid-liquid separation more convenient.

Along with gas and liquids, there are also sands and impurities, which may damage the instruments and flow control valve. Sands and impurities are collected at the bottom of the vessel then removed by the special drainage nozzle of the vessel.

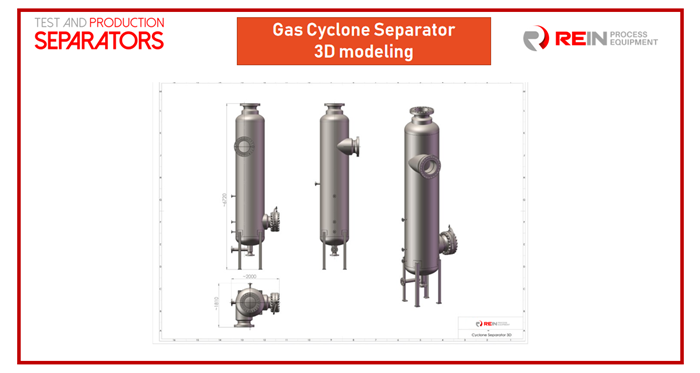

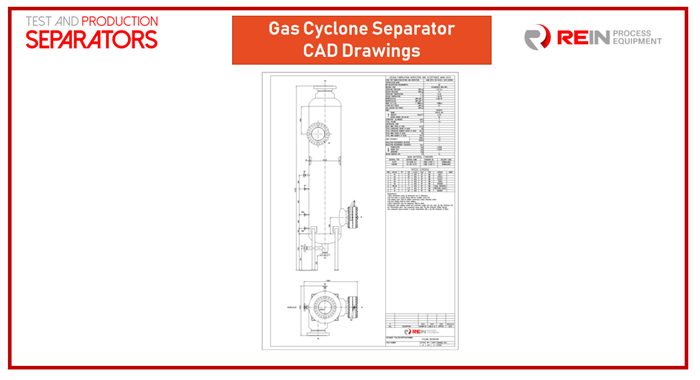

Cyclone Separator are designed as per ASME standards, and usually made from carbon steel. Cyclone separators usually work under high pressure up to 10 MPa. In cold regions, low-temperature steel shall be selected. Cyclone separators can be equipped with pressure gauges, level gauges, safety valves, shut-off valves, and control valves (optional). Manway of the pressure vessel shall be designed as per code & standards and allow easy access to the separator internals. Dimensions of the cyclone separator vessel shall be designed as per flowrate and pressure rating.

Feel free to contact us to receive a quote and technical assistance for purchasing gas cyclone separators from China.